What is Soda Blasting?

What is Soda Blasting?

Soda blasting is a method of removing surface contaminants and coatings by using sodium bicarbonate (baking soda). Compressed air from specialized blasting machines propel particles against the surface to be cleaned.

As the sodium bicarbonate particles come in contact with the surface they burst and release an energy that removes the contaminant or coating. The sodium bicarbonate and blasting machine work in unison to perform this removal process in a nearly non-destructive manner that produces little to no damage to the substrate, depending on composition.

Soda Blasting Applications

The non-abrasive cleaning action of sodium bicarbonate makes it effective for several cleaning processes on a variety of materials. The chart below displays some of the practical uses for soda blast media.

- Metal

- PVC

- Plastics

- Masonry

- Wood

- Fiberglass

- Stucco

- Alloys

- Stone

- Composites

- Aluminum

- Concrete

- Paint

- Graffiti

- Residue

- Grease

- Oil

- Coatings

- Carbon

- Powder Coatings

- Contamination

- Asphalt

- Rust

- Stains

- Mold

- Odors

- Sludge

- Chemicals

- Fire And Smoke

- Tools

- Machinery

- Auto Parts

- Airplane Parts

- Turbines

- Restoration

- Fire Restoration

- Mold Restoration

- Plywood Driers/Ovens

- Mining Equipment

- Aerospace

- Railroads

- Marine

- Trucks / Trailers

- Conveyors

- Cylinders

- Engines

- Monuments

- Farm Equipment

- Anilox Roll

- High Value Parts

- Critical Parts

- Log Cabin

- Plant Equipment

- Food Equipment

- Pulp And Paper Equipment

- Remanufacturing

- Refurbishing

Benefits of Soda Blasting

Sodium bicarbonate is a non-hazardous and environmentally safe blast media. It is a water soluble material that provides a one-step cleaning and stripping process that can remove contaminants and coatings efficiently without damaging most delicate substrates, and avoids a potentially labor intensive manual process.

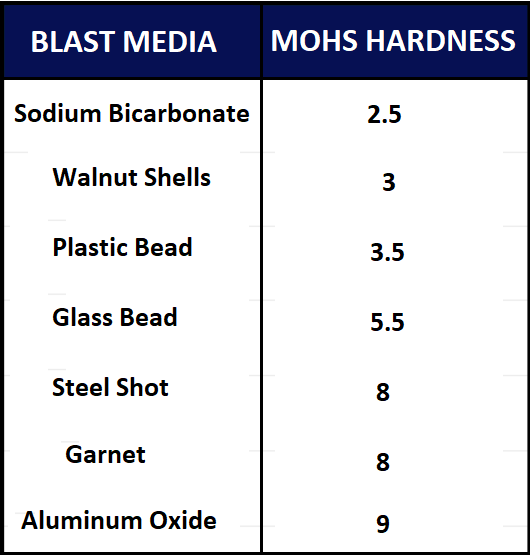

In the abrasive media industry, “hardness” is measured by using the Mohs scale, which is a rough measure of the resistance of a smooth surface to scratching or abrasion.

The relative Mohs hardness of sodium bicarbonate is 2.5, making it one of the more softer abrasives.

Natrium Products soda blast media consists of granular sodium bicarbonate (baking soda) formulated for various soda blast applications. Each formulation consists of sodium bicarbonate particles, uniform in size, that exhibit the flow characteristics needed for productive soda blasting.

Before and after pictures showing the results of soda blasting

Asphalt Tank Truck

Motorcycle Camshaft

Tank Cylinder Part

Soda Blasting Video Gallery

Browse our gallery of videos below to see soda blast media in action! Whether your blast is a DIY project or part of your trade, make sure you’re implementing best practices.

Removal of Heavy Layers

Coating Removal From Tight Spaces

Heavy Military Coating Removal

Paint Removal from Thin Steel

Tell Us About Your Process!

Before you blast, we would like to hear from you. Tell us about your soda blasting needs or simply ask us a question using the link below. An experienced Natrium Products team member will get back to you to discuss. We look forward to hearing from you.