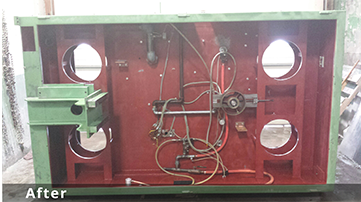

Remanufacturing

Soda Blasting for use in Remanufacturing

With a greater focus on global sustainability and environment protection, remanufacturing is more important than ever. Remanufacturing and rebuilding options help in the conservation of critical resources and cost reduction.

The first and most demanding step in the remanufacturing or rebuilding process is cleaning and stripping the old component (core) of grease, oil, scale, carbon, and other contaminates and coatings, to enable the proper inspection for defects. The cleaning process is essential in determining the quality of the final remanufactured piece, so finding the right cleaning for your job is vital.

Whether you are remanufacturing engines, transmissions, compressors, generators, fuel pumps, or just about anything, soda blasting may be the answer to your cleaning and stripping needs.

Solving your parts & component cleaning needs

Soda blasting with sodium bicarbonate is a superior way to clean and strip in just one step providing a more effective and less time-consuming process. Soda blasting media from Natrium is a soft abrasive, this means that in most cases the soda media is harder than the contaminate and softer than the substrate which eliminates damage or profiling of the substrate. The use of a harder abrasive can cause denting or pitting of the surface and can produce component tolerances that are out of specification. Also, the water solubility of our soda blasting media allows for all used material to be washed away with a simple rinse, so nothing is ever left behind.

Features of Natrium Products Soda Blasting Media:

- One step cleaning and stripping

- Eco-friendly

- Non hazardous

- Non toxic

- Water soluble

- Easy handling and disposal

How does Soda Blasting compare to other cleaning methods?

Solvent cleaners and chemical strippers are often used to perform the same job, but not without risks. This type of cleaner often contains hazardous materials that quickly evaporate and result in harmful vapors in the air. These vapors create fire risks as well as health risks for employees. The handling of these chemicals must always be done with extreme care. The spent material is hazardous and must be disposed of properly. Soda blast media is non-toxic, non-hazardous, and eco-friendly.

Contaminates can also be removed by a heat-treating process. Burn off ovens are often utilized to perform this pyrolysis process. Smoke and fumes are by-products of this chemical decomposition activity; therefore, containment and treatment of these emissions need to be performed. In addition, a residue is often left on the fixtures and parts. This requires a secondary cleaning step to remove, which is often accomplished by the use of a pressure wash. The soda blasting process produces no smoke or fumes that may be dangerous to employees or the environment, removing that extra step of containment and treatment of emissions. Also, soda blasting is a one-step cleaning process that will certainly save you time.

Save time with one step stripping and cleaning. Natrium Soda Blast media provides a gentle but aggressive cleaning of all your parts and components.

Contact Natrium Products Inc. today to discuss your specific cleaning requirements for your remanufacturing process.