Our Story

Natrium Products, Inc.

This quiet little baking soda producer may have just a tiny fraction of the market, but it has a huge impact on the businesses it serves.

It fluffs up pancakes, fizzes Alka Seltzer®, deodorizes refrigerators and scrubs kitchen sinks. It extinguishes fires, soothes insect bites, settles upset stomachs and helps purify swimming pools. And that’s just for starters.

If you haven’t guessed yet, we’re talking about sodium bicarbonate, more commonly known as baking soda—a naturally occurring alkaline substance which is found in all living things and helps maintain a healthy pH balance. The basic building block of baking soda—soda ash—is found naturally in the Earth and is mined to produce baking soda. The substance has an endless array of uses in products for cleaning, deodorizing, leavening, buffering, fire extinguishing, abrasive blasting and more.

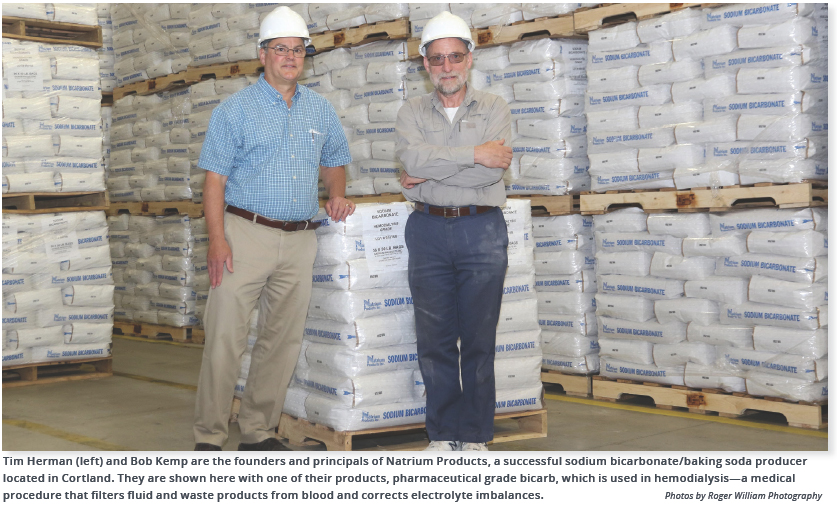

Located at 58 Pendleton St. in Cortland is Natrium Products, a baking soda producer that has supplied sodium bicarbonate to its customers since 1989. Tim Herman and Bob Kemp are the founders and principals of Natrium (a Medieval Latin word meaning “sodium”) who began the business when they saw a demand for the product in the northeast U.S.

“We are so passionate about what we do that some clients refer to us as ‘bicarb geeks.’ I can’t think of a greater compliment.”

-Tim Herman, Natrium Products

Tim Herman (left) and Bob Kemp are the founders and principals of Natrium Products, a successful sodium bicarbonate / baking soda producer located in Cortland. They are shown here with one of their products, pharmaceutical grade bicarb, which is used in hemodialysis- a medical procedure that filters fluid and waste products from blood and corrects electrolyte imbalances.

Photo by Roger William Photography

In 1984, Allied Chemical sold its bicarb business to Church & Dwight Co. and eventually shut the New York-based plant down. Soon after, Church & Dwight Co. shuttered its regional sodium bicarbonate facility as well. As a result, there was no longer a source for sodium bicarbonate anywhere in the U.S. Northeast.

Herman and Kemp saw a real business opportunity and approached Allied Chemical about buying the potassium bicarbonate building. Unfortunately, Church & Dwight Co. got it instead. Nonetheless, the two knew they had a solid business

model, and began casting elsewhere for a plant that would suit their needs.

“Our search initially brought us to Syracuse, but we couldn’t find what we needed,” Herman says. “So we expanded our search, and with the help of the Cortland County Economic Development Agency and Thoma Development Consultants found a couple of promising locations in Cortland. We finally chose the old F.H. Cobb Company facility.”

The principals designed the plant based on market need, while capitalizing on what they saw as three key operational strengths: location (saving on freight costs), size (their operation matched up better with smaller corporations), and product type (focusing production on a higher percentage of courser/granular product).

Natrium’s markets consist of pharmaceutical, water and waste treatment, chemical distributors, sodablasting, and food, animal feed, cleaning products, other consumer products, and other markets. Their client base is primarily located east of the Mississippi and throughout the Northeast, as well as a few nationwide. Natrium Products currently has 25 employees.

“We’re experts in the field and take very seriously what we do,” Herman says. “We are continually refining our operation to meet the needs of customers and the markets we serve. When we meet new customers, our approach is not to simply sell to them, but to go in and learn how they use our product and see if there’s a way to improve on that. This has served us well. We may lose a customer for economic reasons, but never because of service.

“When we started, people thought we were crazy going up against the big guys,” says Herman. “But we’re still here, because we’ve been in the business long enough to know what our customers need in product, service and pricing. Our goal is to be so reliable that they have no reason to switch.

“And when I talk about ‘we’ here, I’m not just talking about Bob and myself,” he says. “I’m also referring to our extraordinary team of employees and to our board.

How Sodium Bicarbonate is Made

Soda ash is initially mined, refined and shipped by train to Natrium Products from the city of Green River in Sweetwater County, Wyoming. At the Natrium Plant, the soda ash is dissolved in a water solution and put into a large holding tank where carbon dioxide (CO2) is bubbled through it. (The CO2 is purchased from ethanol plants that produce it as an off-gas.) The resulting sodium bicarbonate precipitates out of the solution to become a thick paste called “slurry” which is dewatered in a centrifuge to extract any remaining water. The dry bicarb is then screened into various granulations and grades before it is bagged for sale.