Soda Blast Media Products

Natrium Products Inc. offers three soda blast media grades, differentiated only by the average particle size or granulation. All our soda blast media formulations are pure sodium bicarbonate and manufactured with no additional flow agents. The result is better productivity, reduced dust levels, and better solubility in water.

The table below summarizes the key differences of each formula and a general guideline for applications. We recommend trying the Natrium 260 for most applications, but encourage you to contact our experienced sales team to find the best choice for your specific job.

|

|

|

|

|---|---|---|---|

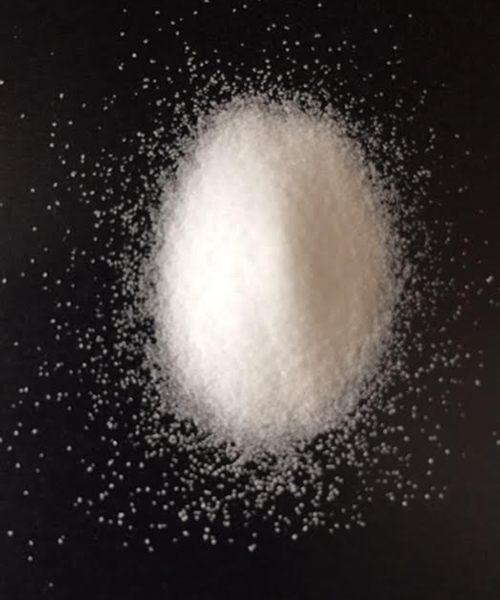

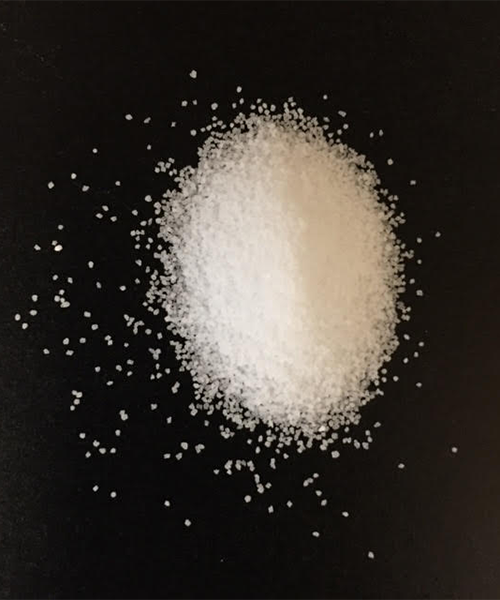

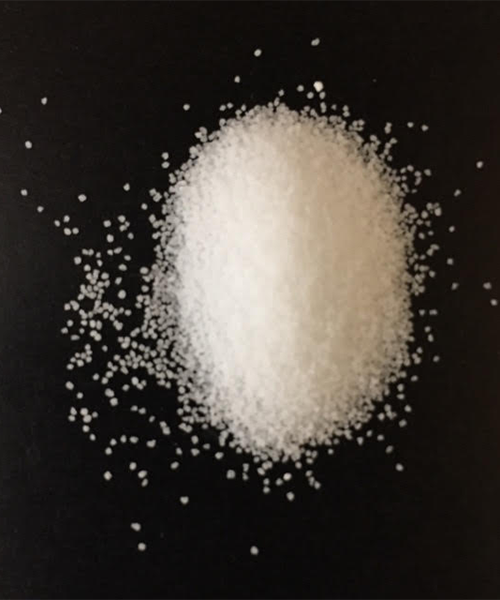

| Formula | Natrium 150 | Natrium 260 | Natrium 300 |

| Mesh | 100 | 50 | 45 |

| Avg. Micron | 160 | 300 | 350 |

| Flow Aid | 0% | 0% | 0% |

| Application | Some fire & mold restoration, wood surfaces, and applications where delicate coating removal & surface preparation with minimal substrate damage are required. | Most fire & mold restoration, automotive & diesel engines, aerospace parts, turbines, pumps, turbo chargers, tanks, valves, and remanufacturing. Heavy coatings. Applications where efficiencies would be realized by degreasing and removing coatings in a single step. | Remanufacturing, or removal of the most difficult coatings where other soda media may have failed. Where the highest productivity and/or the least amount of dust are required. |

*These products can be purchased in both 50lb bags and 2,300lb sacks.

It’s LESS dusty and MORE productive.

Natrium’s soda blast media is generally less dusty and more productive than the competitive products available. Less dusty means being able to see what you are blasting better. More productive means getting the job done quicker with less labor.

How Does Natrium Compare to Other Soda Blast Media?

Natrium Formula 260 compares favorably with the Armex® Maintenance XL Formula or Maintenance Plus. Natrium 150 is comparable to Armex® Maintenance Formula.